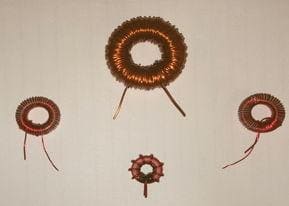

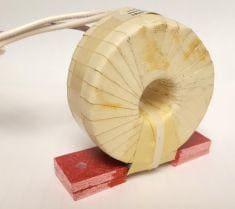

Inductors are electrical components that are designed to oppose currents passing through them. They are primarily used for signal processing and analog circuits. In Switch Mode Power Supply (SMPS) devices, they are used as energy storage components.

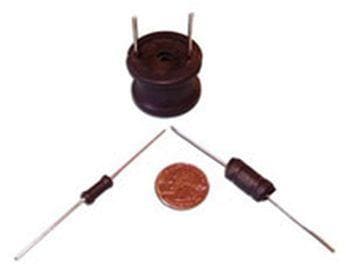

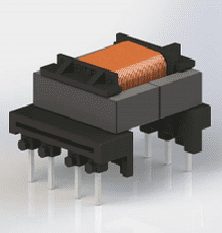

There are a variety of inductors available in the market. There will always be a difference in terms of cost, size, and performance. Choosing the right type of inductor will make a big difference to your application. Here, we provide you a few tips to choose an inductor.

Factors to Consider

There are certain points that need to be considered when looking at inductors.

-

- Application: There are two main aspects that an engineer looks at in an inductor – whether it meets the circuit requirements, and whether the inductor improves its performance. Generally, inductors are used either for power circuits, or for Radio Frequency (RF) interference prevention. Understanding the application requirements will help an engineer to choose the right type of inductor.

-

- RF Applications: If you are choosing an inductor for an RF application, then there are two aspects you need to consider. First is the quality or Q factor. This refers to how the inductor’s resistance value. A high value Q is always preferred. The second aspect is the Self-Resonant Frequency (SRF). It is the frequency when the component stops acting like an inductor. The minimum value of SRF is always chosen.

-

- Power Applications: If your application comprises power circuits, two current types need to be considered – maximum and incremental currents. Incremental current refers to the current level where inductance is reduced. Maximum current is when the inductor’s current level exceeds the application device’s temperature.

-

- Size: The size of the inductor also makes a difference to an application. Large sized inductors are used for power circuit applications. They are used in congruence with filter capacitors. Small sized ferrite core inductors are used for RF applications, as the power requirement will be less.

-

- Tolerance: An engineer can understand whether the inductive value of a device is different from the datasheet by looking at the tolerance percentages. For example, a device with 10% tolerance will provide up to 0.9 mH, and not 10 mH.

- Shielding: The inductors need to comprise shielded components. This can reduce magnetic coupling between components. This is an effective solution, especially in space constrained applications.

These various factors can help you to choose an inductor for your application. Always check the datasheets provided by the manufacturer to confirm the specifications. Get all your queries answered before selecting a product.