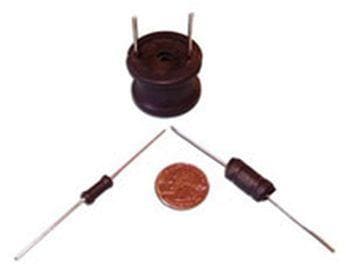

Antenna coils are self-supporting coils that often have a high number of turns. These coils not only provide coupling to any other circuit, but can also be used for increasing inductance of the circuit after insertion. The target resonance of an antenna can be met with the help of an antenna coil.

Which features make antenna coils durable and reliable?

These days, there are many manufacturers in the market who provide antenna coils. However, you need to judge them by certain criteria and distinctive features:

- Manufacturers should design the coils keeping in mind the requirements of specific industries

- A user-friendly antenna coil can be wound so that it can interface with almost any circuit.

- Coils which are self-supporting and are made with fine gauge wire are highly recommended

- Bond-able wire works very well with many of the operating current requirements and hence its use in antenna coil; adding to the reliability and functional efficiency of the coil

- Antenna Coils should not only be cost-effective but they should also help in saving your company manufacturing time

- When the coil is manufactured utilizing equipment like arbors and winding mandrels, (which are extensively used to provide winding of fine gauge wire) it increases the flexibility in overall size and shape of the antenna coil.

How to generate a current in antenna coil?

Generally, antenna coils use chemically activated adhesive agents to bind the windings instead of the conventional cumbersome bobbin-wound coils. These completed units can be placed in a magnetic field, and movement in that field can be used to create different currents.

When properly designed and wound, an antenna coil can prove to be highly efficient in increasing the inductance of the circuit.

By chalking out your requirements and studying the available options, you can select the best suited Antenna Coils for your equipment.

Meet your expectations by requesting a quote for Antenna Coils.