Electric circuits may vary in design and operation across different industries. However, there are certain components of these circuits that remain common to all. Inductors are one such component that are very common. These are passive components that provide energy storage and are identified by their inductance value and current rating. Due to their popularity there are different types of inductors available in the market and they are distinguished based on their size and ratings. Are you intrigued to know what these different types of inductors are and how they work? Read the post to know more.

A General Introduction to Inductor and Its Working

It is a well-known fact that conducting materials are either ferromagnetic or paramagnetic. As such, non-conducting materials are diamagnetic in nature. Due to their nature, most conductors show inductance whenever there is a change in the direction of current or when reverse flow of current is observed. In simple terms, inductance can be referred to as the opposition shown by a conducting material in response to the electric current flowing through it. Inductors are electrical components that feature a shaped conductor which increases the inductance of the device by boosting the magnetic flux. Any change in this magnetic flux may induce an EMF or voltage in the circuit.

Generally, wires wound into helix or coil-shaped structures serve as conductors in these inductive components. The wire shaped as a coil has a higher inductance than a straight wire as magnetic lines pass through it several times. This gives rise to multiple flux linkages. In a device with a full flux linkage, the inductance is the square of the number of turns in the coil.

Power inductors are very popular types of inductors used today. These devices are mainly used in electrical circuits that are subjected to high current and large voltage fluctuations. The power inductors often store energy in DC-to-DC converters and are combined with capacitors to tune circuits like TV receivers and radio.

A Few Types of Inductors Discussed

As said before, there are different types of inductors available for consideration. The following are a few popular ones that are widely used across industries.

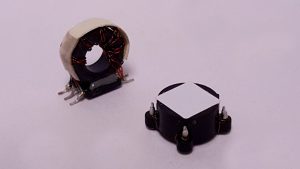

- Surface Mount Power Inductors: These power inductors are sometimes referred by their abbreviation SMD. They are often used in power circuits that are miniaturized. Surface mount power inductors are used in electronic applications that use AC-to-DC converters and DC-to-DC converters. In addition to this, they are also used in graphic cards, battery-powered devices, desktops, notebooks, PDAs, and even server applications.

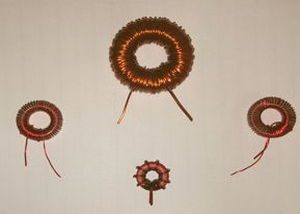

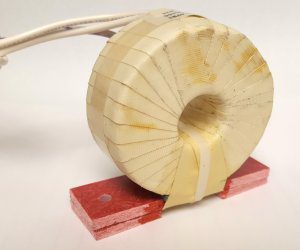

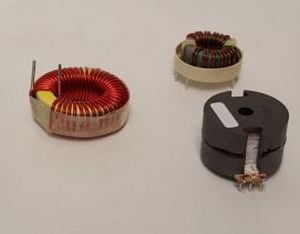

- Toroidal Inductors: These inductors receive their name from their donut shaped magnetic cores. Toroidal inductors possess a specific current carrying capacity and inductance and are typically used in power circuits. They support low frequencies without affecting the large inductance values. A Toroidal inductor typically has a higher inductance per turn than other type inductors using different cores. The inductors of this type are also capable of carrying large currents. The versatility of these type inductors allow them to be used in a wide range of circuits such as amplifiers, EMI circuits, medical devices, air conditioners, switch mode power supplies, electronic brakes and clutches, and so on.

- Air Core Inductors: Unlike all other inductors listed here, these inductors feature a non-magnetic core. The coils are usually wound on plastic forms or the coils can be made as self-supporting by winding them with bondable magnet wire. These inductors possess no core losses like other inductors made with ferromagnetic cores. Also, the absence of a ferromagnetic core makes them saturation-free. These inductors assure reliable performance at high frequencies and are often used in applications with radio and microwave frequencies. Air core coils are widely used in applications such as signal transmission, signal transmission systems, radar equipment, air navigation systems, land mobile radio systems, and marine communication equipment.

- Ferrite Inductors: As the name suggests, these transformers use ferrite cores. Generally, the ferrite cores are produced by mixing iron oxide with other metal oxides like magnesium or zinc oxide at very high temperatures. These inductors display high electrical resistivity, permeability, as well as low eddy current losses. Due to these sought after features, ferrite inductors are used in switching circuits, as well as medium and high-frequency applications. They are also used in noise filtration equipment, industrial converters, switching regulators, and so on.

The type of inductor you choose will depend on your specific application requirements. Custom Coils offers many types of inductors that can be customized to meet your specific requirements. The steady performance of these magnetic components makes them popular with many industrial clients. Custom Coils’ engineers can work closely with you to understand your requirements before selecting the inductor you need for an application.